1. INTRODUCTION

2. BENEFITS OF THE UNDERGROUND COLD STORAGE

3. CONSIDERATION OF THE STORED GOODS

3.1 Cold storage for fruits and vegetables

3.2 Coffee storage

3.3 Wine storage

3.4 Storage of lilly bulbs

4. THREE CANDIDATE SITES FOR THE CONSTRUCTION OF THE UNDERGROUND COLD STORAGE

5. CONCEPTUAL DESIGN

5.1 Design of the Lac Duong Storage

5.2 Design of the Duc Trong Storage

5.3 Rock support design

6. CONSTRUCTION PLAN

6.1 Quantity of excavation

6.2 Excavation plan

6.3 Excavation schedule

6.4 Estimated construction cost

7. BUSINESS MODEL

7.1 Revenue model

7.2 Business structure

8. CONCLUSION AND RECOMMENDATIONS

1. INTRODUCTION

Lam Dong Province belongs to the south western highland area of Vietnam. The area of Lam Dong Province is 9,765 km2 and the population is around 1,140,000. Including Da Lat City, the altitude of the north eastern part of Lam Dong is higher than 1,000-1,500 m. With the high altitude environment, the temperature of this area is yearly stable as 18-25°C, which provides the special conditions to grow all kinds of tropical fruits and vegetables without seasonal variations.

The agricultural industry of Lam Dong Province has been growing in volume and in kinds and types of produces. In 2012, the annual growth of agriculture in Lam Dong has achieved a high rate of over 10% and the proportion of agricultural products accounts for 46% of the provincial GDP and accounts for 80% of the export value. It is expected that the growth of agriculture in Lam Dong will keep its rate very steadily or more till 2020. Moreover, by introducing hi-tech technologies like hydroponic, the productivity of vegetables and flowers is increasing. The export of coffee was 111.6 mil.US$ in 2015, but it was recorded 250 mil.US$ in 2018. The export of vegetables was 20.4 mil.US$ in 2015, and 34.5 mil.US$ in 2018. Large volume and various produces of vegetables, fruits, flowers and coffee is the characteristics of agriculture in Lam Dong.

On the other hand, with solid base rocks in the geology of Lam Dong, the mining which produces aggregate becomes one of the essential industries in Lam Dong. Since the mining is carried out by open cut, the loss of land and the contamination of water cannot be avoided. Also, the expansion of quarries will damage the good scenery of highlands. It is known that currently 42 quarries are under operation and 30 quarries are abandoned in Lam Dong.

BCMP and RIGPE (Research Institute of Geology and Petroleum Engineering) of Ho Chi Minh University of Technology suggested the construction of underground cold storage using the abandon quarries to the Local Government of Lam Dong.

The chronology of the project so far is as below;

2017.10.23. Presentation of “Introduction to Underground Cold Storage” for the People’s Committee of Lam Dong Province; Vice Chairperson ordered to submit the proposal of feasibility study by the end of November.

2017.11.30. Submission of ‘A Proposal for the Feasibility Study’

2018.01.10. Conclusion of MOU between three organizations; DONRE (Department of Natural Resources and Environment of Lam Dong)-BCMP-RIGPE

2018.04.18. Presentation of the proposal for the prefeasibility study

2018. 05. 29-30. Drone photograph works and meeting with local farmers and government officers

2018. 08.31. Submission of the Final Report on the Prefeasibility Study

2. BENEFITS OF THE UNDERGROUND COLD STORAGE

When the cavern in hard rock is utilized as the cold storage, it has many benefits comparing to the traditional aboveground cold storage. Since the rock itself acts as the insulations, artificial insulation, mainly using polyurethane foam, is not necessary. With big mass of rocks, the cold storage is not affected by the seasonal variations of the temperature. Therefore, it is expected that the energy consumption of the underground cold storage becomes very constant over the year, which can result in the energy savings.

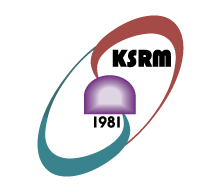

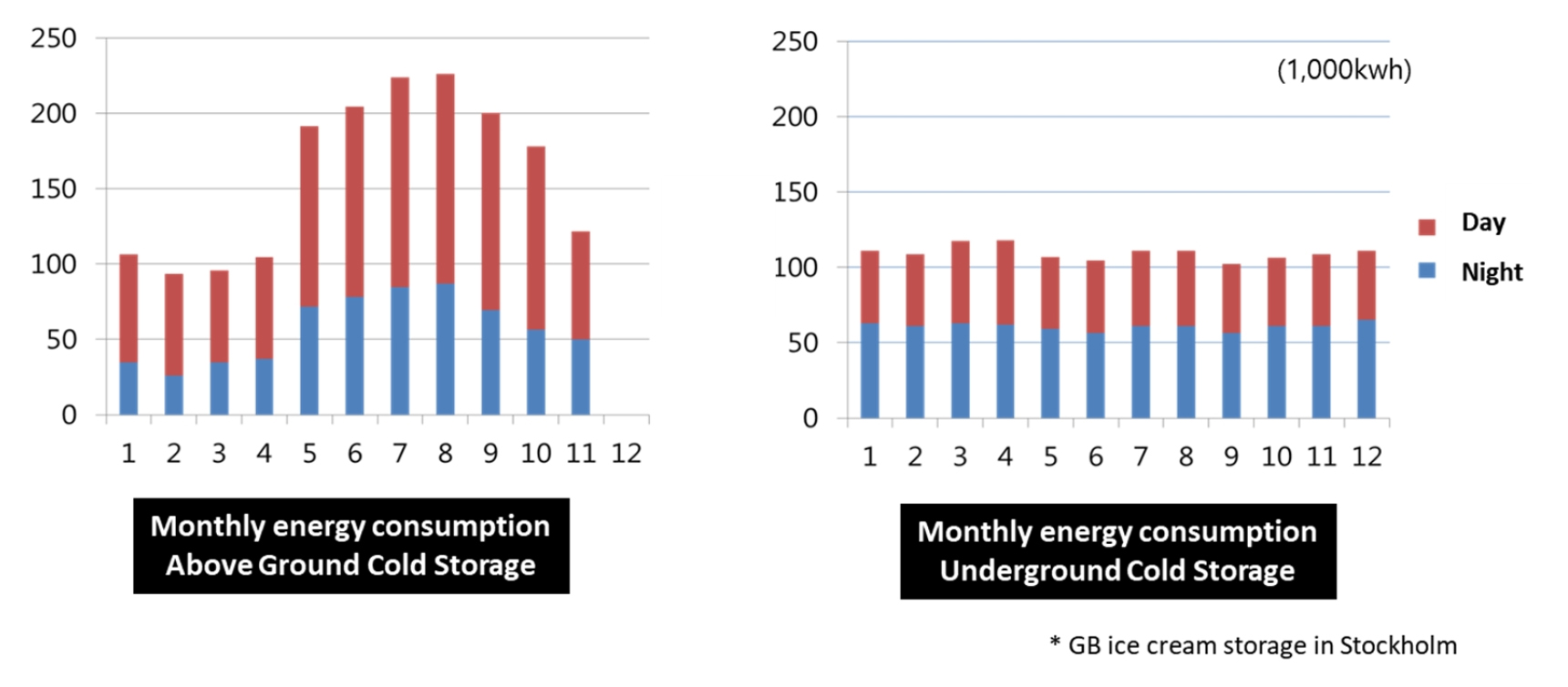

Fig. 1 shows the yearly energy consumptions of the aboveground and the underground cold storages. Since the capacities of two storages are almost the same, it is easily understood that the amount of energy consumption of the underground cold storage is 30-40% less than the aboveground. Fig. 2 shows the daily electrical loads of above and underground cold storages. Regarding the thermal capacity of rock mass, the design capacity of cooling plant of the underground storage can be reduced comparing with the aboveground cold storage (Kim et al., 1997).

Another significant benefit of underground cold storage is the time-based stability and the spatial uniformity of the temperature distributions inside the storage. This characteristic keeps the quality of stored foodstuffs consistent for a very long time.

3. CONSIDERATION OF THE STORED GOODS

3.1 Cold storage for fruits and vegetables

Cold storage is widely used for bulk handling of perishable fruits and vegetables during the process of logistics. When storing several produces in the same room, care must be taken to store the kinds of produces which could not be well stored because of the storage compatibility. In order to resolve the incompatibility during cold storage, foodstuffs are grouped into three temperature ranges.

Based on their thermal incompatibility, the products are classified into;

1) Most vegetables, not sensitive to cold (0-4°C), e.g., apple, grape, carrot and onion

2) Vegetables moderately sensitive to cold (5-8°C), e.g., mango, orange, potato and tomato (ripened)

3) Vegetables sensitive to cold (>8°C), e.g., pineapple, banana, pumpkin and broccoli.

Table 1 shows the recommended temperature and relative humidity, and approximate transit and storage life for some fruits and vegetable crops (Krishnakumar, 2002). According to this table, the fruits and vegetables shall be grouped and the storage also shall be designed properly in their temperature and relative humidity according to the selected vegetable groups. In order to extend the storage duration of foods, the CA and MAP film can also be considered.

Table 1.

Example of the recommended optimum storage temperature and RH for different fruits and vegetables (Krishnakumar, 2002)

3.2 Coffee storage

In Lam Dong Province, recently, the large scaled coffee farms are fostered and the coffee bean production is steadily increasing. Coffee bean, especially called green bean, is produced through several steps named coffee chain (International Coffee Organization); picking, processing (through wet, dry or semi-wet process), hulling, polishing, cleaning and sorting. Generally, the sorted beans are then stored in 60 or 70 kg sacks called sisal bags that help the beans retain moisture for more extended period. The storage time cannot exceed one year for the beans to be considered a current crop (Wikipedia, 2012). Generally speaking, the enemies against stored coffee bean are moisture, light, and temperature. In order to design the underground coffee storage, we need to know deeper about the mechanism of long term storage and its deterioration of quality.

Regarding the bulk storage for coffee beans, operations are important from the point of view of ochratoxin A (OTA) prevention and quality assurance. The ‘time’ element involved in storage operations provides an opportunity for microbiological and biochemical processes to lead to quality deterioration according to the condition of storage – particularly temperature and relative humidity. According to the research works, moisture is more governed in OTA production. In conclusion, coffee bean storage should maintain the relative humidity less than 60-70% and the humidity shall be kept stable. Since underground storage is relatively sealed, it is considered that manipulating the RH is rather easier than aboveground space.

3.3 Wine storage

In Da Lat City, there is a very old winery, named Ladora. Ladora winery has produced around 2 million bottles of wines including apple juice in 2017. The wines produced in this winery are currently delivered in domestic market, and with good appraisals it is known to prepare export to foreign countries. In order to upgrade the quality of wines in Ladora, the producers are required to consider the better conditions for aging and storing longer period of wine. Among the several parameters which control the aging process, the temperature is the most crucial factor. Several studies suggest optimum environment for the aging of wines. In conclusion, each wine has its own best environment primarily related to the temperature, and the temperature shall not be higher than 20°C and lower than 4°C.

Many authors suggest the ways of designing wine cellars to achieve the required environmental conditions, emphasizing the advantages of underground construction for thermal stability (Martin and Canas, 2006).

3.4 Storage of lilly bulbs

Lilies are one of the most important bulbous plants for production as cut flowers. In 2009, the Netherlands exported 1.2 billion large bulbs of lily, which are ready for flowering, and the main importing countries are, America (270 milllion bulbs), Japan (138 mil.), China (110 mil.), Mexico (97 mil.), Taiwan (70 mil.), Australia (54 mil.) and Korea (26 mil.) (aT, 2009). Korea has tried to develop the growing method of lilies for a long time, and in recent years Korea has successfully delivered the bulbs of localized lily cultivars in domestic market and their market share was 8.5% in 2017.

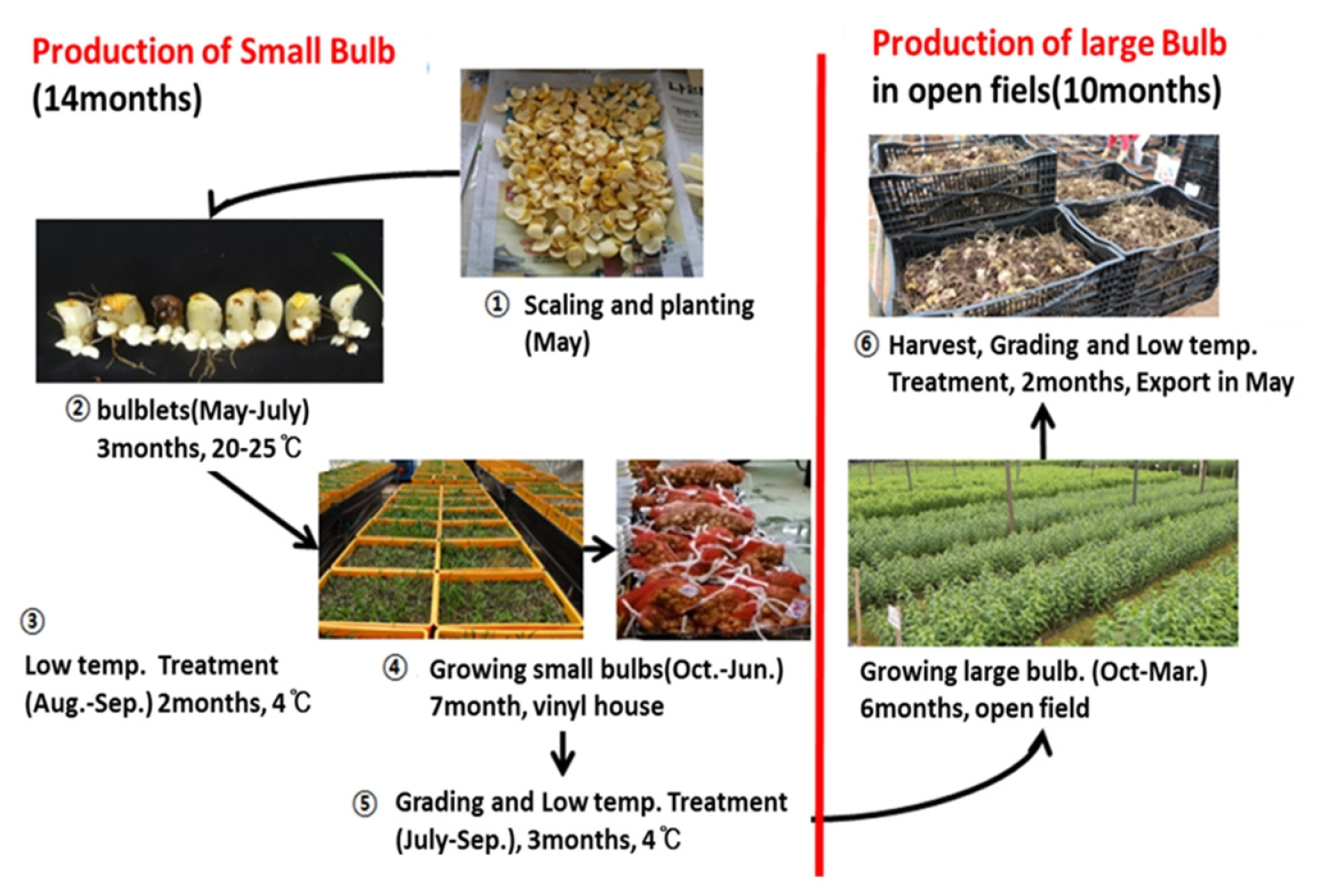

The cooperative national project between Vietnam and Korea is under operation in Dalat, of which purpose is to establish the production system of large-sized lily bulbs from scaling. Fig. 3 shows the process of producing large-sized bulbs of Asiatic and lilium longiflorum and it is revealed that the whole process takes more than 24 months in total (Lee, 2006). In case of Orientals, the process is almost same and the total duration takes more than 28 months (Lee, 2016). During the process, it is required long term low temperature treatments in three steps, 2 months in Step 1, 3 months in Step 2, and finally at least 2 months in Step 3, and the required temperature is 4°C.

Another requirement for the production of lily flowers is controlling the timing of planting and flowering to get the time advantages in flower market. One of the main problems is the long duration of harvest from the planting of bulbs. Since Asiatic and Oriental lilies were originated in the cold area, they need cold sleep in winter type. According to the research works, the proper temperature and duration of cold storage of lily bulbs showed a striking performance in dark sprout and flowering in field. For example, when the bulbs are stored in 6 months with the series of temperature changes like, 2 weeks in 15°C, 4 weeks in 4°C, 14 weeks in -1.5°C, 2 weeks in 4°C, and 2 weeks in 15°C, the duration of dark sprout from planting takes 3-6 day, and the duration of flowering takes 84-107days. This is quite good results comparing with the traditional days, sprout 69 days and flowering 246 days (Kwon et al., 2003). In low temperature treatment and storages, the stability of temperature is also very important. If the temperature varies in a certain ranges lower and/or high than the designed ones, the bulbs are weak and vulnerable to harm. Therefore, the underground cold and chilled storage system for lilies bulbs can provide benefits to lily bulb storage with the characteristics of underground conditions which keep the temperature and humidity very stable.

THREE CANDIDATE SITES FOR THE CONSTRUCTION OF THE UNDERGROUND COLD STORAGE

The government of Lam Dong Province recommended three abandoned quarries as the candidate sites for the underground cold storages; in Da Lat City, Lac Duong and Duc Trong District. Since the geology of the Da Lat quarry was not favorable to build the cold storage, it was excluded from the candidates.

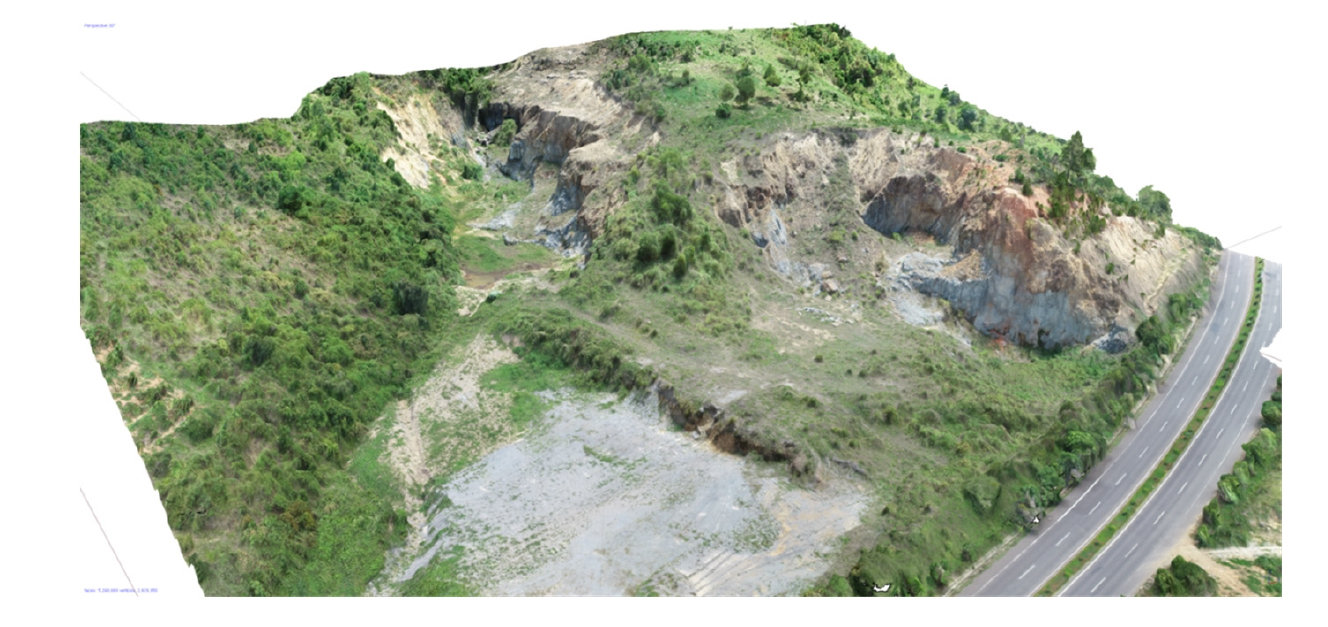

Fig. 4 shows the picture of the quarry in Lac Duong. The top soil layer shows the critical circular failures. But the bed rock is Andesite with fair to good qualities. Before the construction of the underground cold storage, some site preparation works will be needed for the protection of the soil failures.

Fig. 5 shows the three dimensional solid model of the quarry in Duc Trong. The rock is Andesite with good to very good qualities. One shortage of this site is that the topography is relatively shallow. Therefore, the access tunnel shall go deeper to reach the proper locations.

5. CONCEPTUAL DESIGN

5.1 Design of the Lac Duong Storage

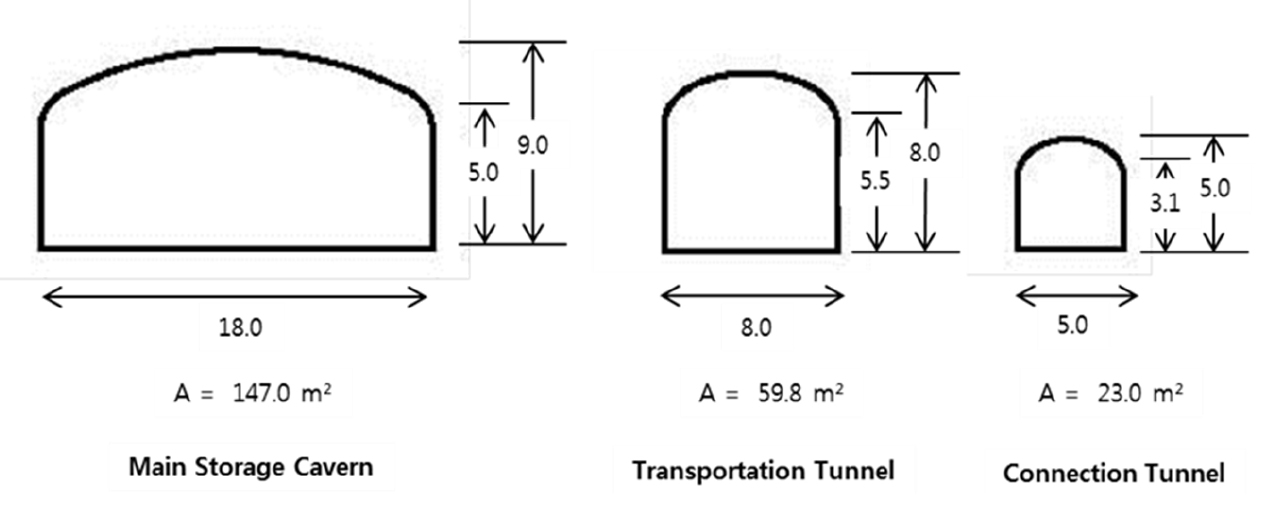

The main philosophy of the construction of the storage cavern is that the rock support shall be optimized with rock bolt and shotcrete. Therefore, the width of the cavern shall be carefully designed. Considering the geology of Lac Duong quarry, the width of the main storage is designed as 16 m. The size and shape of tunnels shall be finally determined in the detail feasibility study with detail geological investigations.

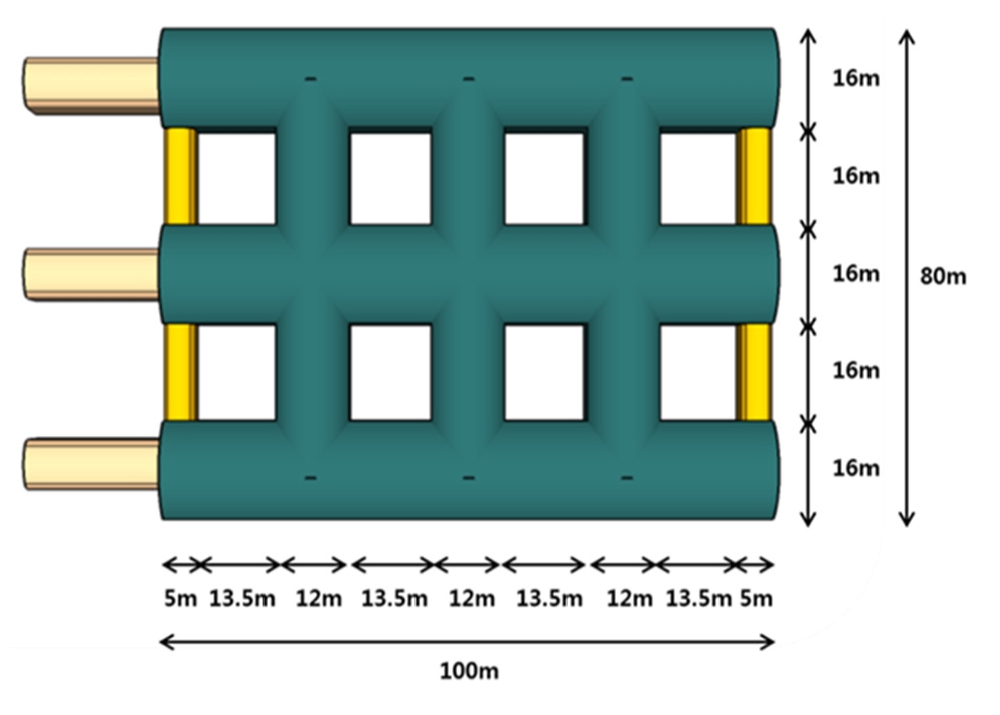

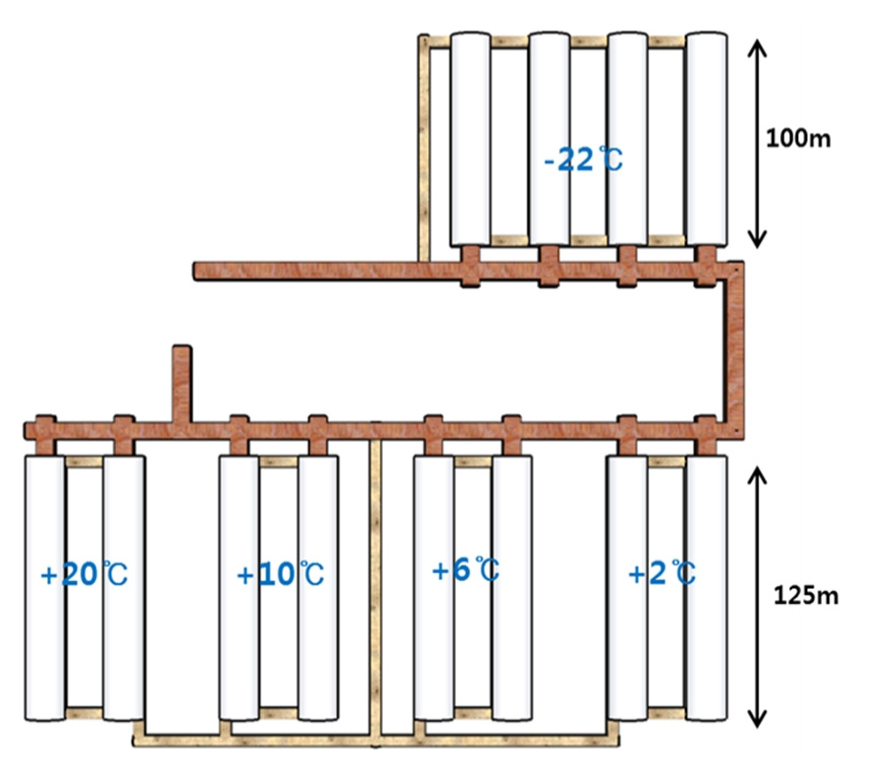

Fig. 6 shows the single storage unit for chilled storage with various temperatures. For the design of the cold storage cavern, some factors were considered; effectiveness of stock with standard pallets, smooth movement of forklift inside the caverns, the efficiency of the space usage and others. The storage unit comprises three (3) parallel caverns of 16m wide, and three (3) crossing caverns of 12 m wide. Two small cross tunnels of 5m width connecting the end parts of each cavern will be used for the transportation purposes of forklifts. The floor area of one storage unit is 6,272 m2.

One storage unit has three loading and unloading stations in the connection points of the access tunnel and the storage. It is designed that the refrigerator truck can be reached to the loading station. Fig. 7 shows the photo of the underground loading and unloading area which is constructed in USA.

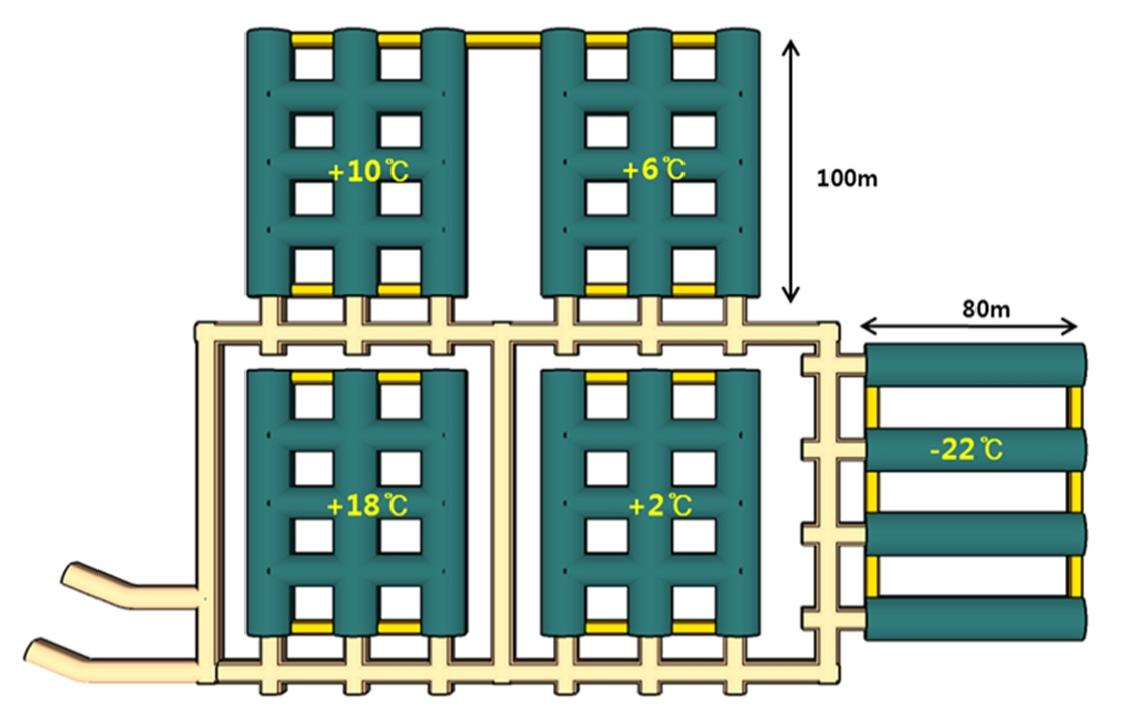

Fig. 8 shows the overall layout of the underground cold storage in Lac Duong. The storage contains four chilled storage units with different storage temperatures and one unit of frozen storage. The total floor area is 30,208 m2, and storage temperatures were designed as five types; 18°C, 10°C, 8°C, 2°C and -22°C.

5.2 Design of the Duc Trong Storage

During the site reconnaissance survey, it was observed that the quality of rock mass in Duc Trong quarry is very good. Therefore, the width of the main storage cavern is designed as 18 m. Fig. 9 shows the typical cross sections of tunnels.

Fig. 10 shows the overall layout of the Duc Trong Underground Cold Storage. Five types of storage temperature were considered, as -22°C, +2°C, +6°C, +10°C, and +20°C. The total floor area of Duc Trong storage is 25,200m2. In the design, the main considering points were the effective arrangement of the storage units, the length of access tunnel and the people’s safe movement.

5.3 Rock support design

Rock support design for tunnels has been carried out based on Q-system. Rock type in Lac Duong and Duc Trong is classified in two types as “good rock” with Q-value 10-40 and “fair rock” with Q-value 4-10. The detailed analysis and classification shall be done by the results of geological investigations during the “Detail Feasibility Study”.

6. CONSTRUCTION PLAN

6.1 Quantity of excavation

The excavation quantities for the construction of Lac Doung and Duc Trong storages are summarized in Table 2. Since the back-up facilities like pump pit, underground sub-stations, underground work shop for vehicles including forklift, and other related facilities, were not drawn in the conceptual designs, the additional excavation was considered as 10% of the quantity calculated from the conceptual design. Therefore, the total quantity of underground excavation for two sites is 682,500 m3.

Table 2.

Excavation quantity of Lac Duong and Duc Trong storage

| Tunnel | Lac Duong (m3) | Duc Trong (m3) | Remarks |

| Transportation tunnel | 73,900 | 51,000 | |

| Connection tunnel | 9,200 | 18,500 | |

| Storage cavern | 251,800 | 216,000 | |

| Additional | 33,500 | 28,600 | 10% |

| Total | 368,100 | 314,100 |

6.2 Excavation plan

All underground excavation will be carried out by the drill and blast method. In order to reduce the excavation cost properly, it is planned that the excavation works of two storages in Lac Duong and Duc Trong will be done one by one. Regarding the site preparation works, it is planned that the excavation works in Duc Trong will be started first. In order to improve the effectiveness of blasting works, the full face blasting shall be applied, and the excavation equipment shall be selected properly.

Table 3 shows the planned combination of excavation equipment, i.e., jumbo drill, charging car, shotcrete machine, dump truck and others, which is selected to fit the size and shape of tunnels. This combination will be applied as same to the excavation works in Duc Trong and Lac Duong. The excavated rocks will be utilized as aggregate.

Table 3.

Example of the combinations of excavation equipment

6.3 Excavation schedule

The total period of excavation works in Duc Trong site is estimated 17 months including mobilization. Net excavation duration is estimated 14 months. In case of Lac Duong, the total civil construction works are estimated 18months including mobilization and site preparation.

Fig. 11 shows the total project schedule including the plant installation works.

6.4 Estimated construction cost

Two storages with storing capacities of 45,000 tons for Lac Duong and 38,000 ton for Duc Trong were designed. With the conceptual design of storages, total construction cost was estimated. To build both storages in Lac Duong and in Duc Trong, it is estimated that the unit construction cost is 869 US$/m2. Since we don’t have reference data with the same size of cold storage in Vietnam, it is not easy to reckon the economy of the construction cost of this project. However, if we consider the unit cost for building the cold storages in USA which is known as 1,650-1,770 US$/m2 and the unit price in Korea which is almost the same in USA, the estimated unit price in this project has some relative meaning.

7. BUSINESS MODEL

7.1 Revenue model

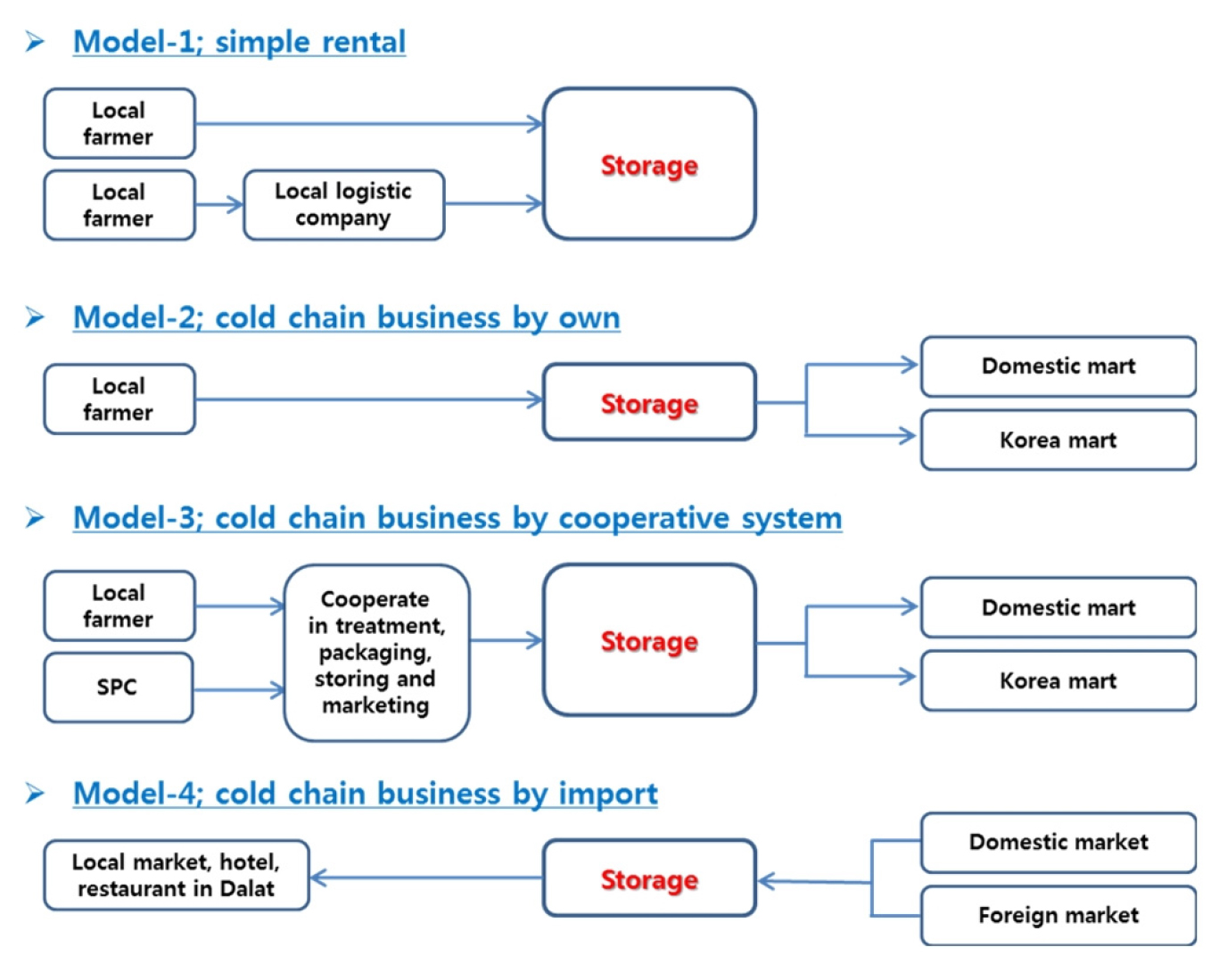

For the operation of cold storage, four types of revenue models can be considered as shown in Fig. 12. In principle, the owner can make cold chain business through export and import as well. Regarding the export case, Model-3 shall be primary without any doubts. Comparing with the simple model, Model-3 can provide more chances to create additional values for the agricultural industry in Lam Dong. Regarding the import case, Model-4 shall be considered as a side works of cold chain business.

7.2 Business structure

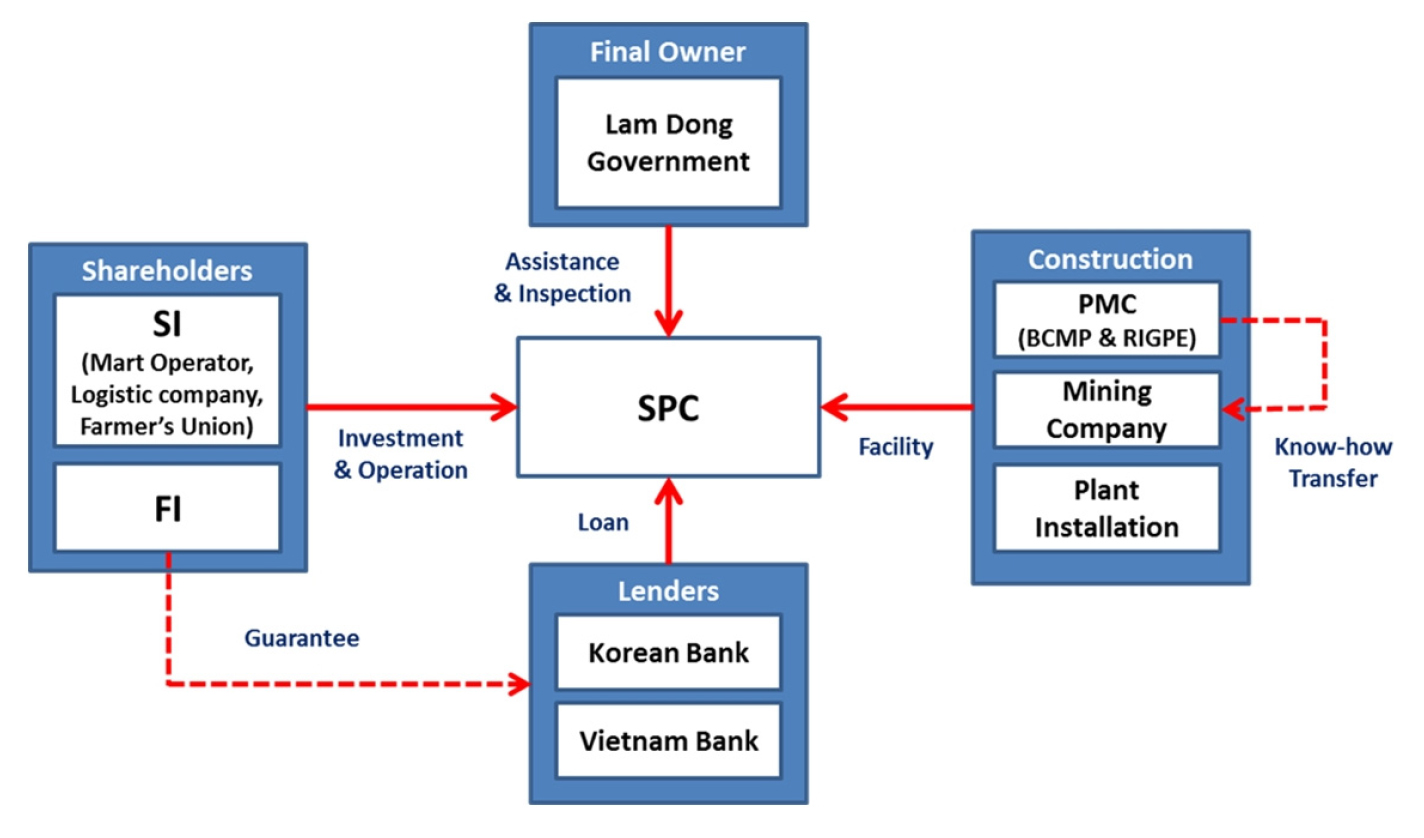

Considering the size of the project, it is recommended that the project shall be promoted using BOT business model and project financing. In case of BOT and PF business, there are many stakeholders for completion and operation & maintenance of the project as shown in Fig. 13. This model is considered as an example and it is required that the proper business model for this project shall be further discussed in the detail feasibility study.

8. CONCLUSION AND RECOMMENDATIONS

Keeping up with the recent development of agricultural industry in Lam Dong Province, especially characterized by wide range of produces, it is expected that many kinds of agricultural infrastructures shall be provided on time and in proper locations. Chilled and cold storage will become one of them. Getting large and proper sized cold storage means the formidable challenges to logistics of agricultural produces and to hold lots of business opportunities to the local farmers and logistic companies.

In this prefeasibility study, the viability of construction of underground cold storages using abandoned quarries was tested in the technical and economic point of views. Since the existing quarry can provide easy access, open and plane land resulted from former excavations, and the fresh rock slopes to make portals, it is relatively easy and cheap to develop underground spaces.

It was concluded through site reconnaissance that two quarries located in Lac Duong and Duc Trong have good base rocks and proper topography to develop underground spaces for cold storage. By investigations through publishes and questions to local farmers, it is requested that the cold storage to be built in this area shall accept various kinds of vegetables with proper storing temperatures and the size shall be larger than 10,000 tons.

The conceptual design of underground cold storage for two quarries in Lac Duong and Duc Trong was presented. In order to converge on the requirements of storage that could keep various kinds of produces with proper capacity, sufficient floor areas were assigned for the storages with different storing temperatures. The size and shape of tunnels and the reinforcement was designed considering the quality of rocks and surrounding topography. In order to promote the project to be started and operated, we suggested the revenue model BOT approach model.

With the output of this prefeasibility study, we expect to introduce investors and through the collaborations with the strategic investors who have the experiences in logistics and sales of agriculture produces, we can perform the detail feasibility study as the next step. In the detail feasibility study, we can develop the basic and detail design, economic model and evaluations customized to dedicated cold chain business in Lam Dong Province.